Global Alloys supplies all nickel alloys for high-tech uses, in collaboration with leading European steel mills, manufacturers and distributors, we are able to supply every product intended for industries such as: aerospace, aeronautics, defence, racing, energy, oil & gas, plants purification plants and exchangers, petrochemical and chemical plants.

AISI F44

Other Specifications:

F44 / S31254 / DIN1.4547/ 254SMO ®;

6MO;

EN10088-3 / A182 / A276 / A479)/ NORSOK M630-MDS R17 BAR ;

M630-MDS R14 FORGINGS M630-MDS R15 PLATE ;

M650

Manufacturer qualification

Alloy 254SMO / 6Mo / F44 is a fully austenitic alloy containing 6% Molybdenum and offers excellent corrosion resistance in a wide variety of aggressive aqueous environments.

It replaces conventional austenitic stainless steels ( AISI 316 and 317 ), where their capabilities are pushed to their performance limits. The alloy, therefore, falls into a “super austenitic stainless steel” category. It may also represent an economical alternative to higher nickel alloys in some marine and chemical processing environments. Alloy S31254 / 1.4547 is particularly suitable for handling high chloride environments such as brackish water, sea water, caustic chlorides and paper mill bleach systems.

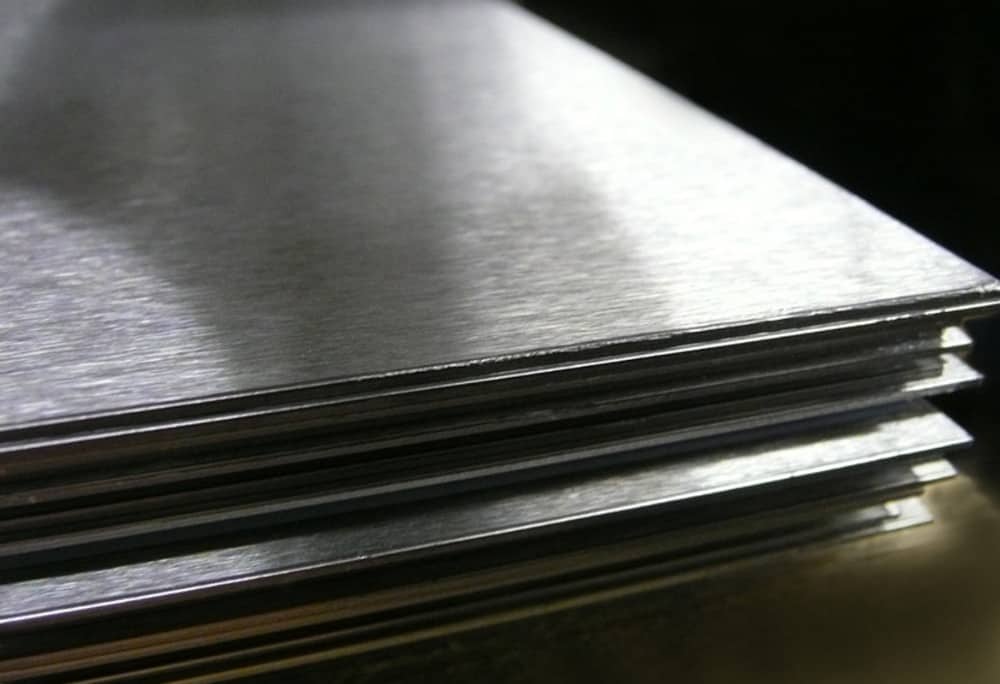

Alloy F44 / 254 SMO is supplied in:

- Sheets and plates

- Rolled plates and forged plates

- bars, round billets, ingots

- perforated bars and tubes

- forged rings, forged flat and round bars

- custom forged elements

MAIN APPLICATIONS:

- equipment for marine and offshore platforms,

- chemical and food plants, salt evaporators

- plants for bleaching cellulose and paper,

- pollution control systems, air and condenser pipes, service water pipes and feed water heaters for the energy industry.

MAIN CHARACTERISTICS

- This super-austenitic material is NACE and NORSOK approved

- Excellent resistance to corrosion in sea water and in the presence of concentrated halides

- High resistance to stress corrosion

- Resistant to crevice corrosion in sea water

- Good resistance to erosion corrosion

- Excellent ductility and impact resistance at ambient and subzero temperatures

- Low magnetic permeability

OTHER STANDARDS:ASTM / ASME A.SA 182; ASTM / ASME A.SA 276; ASTM / ASME A.SA 479; ASTM A370; NACE MR01-03; NACE MR01-75; ANSI / NACE ISO 15156; ASTM G48 METH.A (50°/24H); ASTM A262 Practice E; EN / ISO 3651-2A SENSITIZED T1; PED 97/23 / EC; ASTM A388; API 6A PSL3